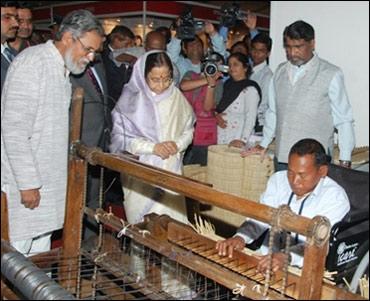

President Pratibha Patil inaugurated the three-day exhibition at Rashtrapati Bhavan on Monday. The exhibition has been hosted at Rashtrapati Bhavan since 2010, as the President wished to give grassroots innovators, a platform to showcase their amazing innovations.

The exhibition is organised by the National Innovation Foundation (NIF), a grant-in-aid institute under the Department of Science and Technology (DST) set up in February 2000.

The mission of NIF is to make India a global leader in sustainable technologies by building upon genius of grassroots technological innovators and traditional knowledge holders.Madhya Pradesh

Many times, in a standing crop, soybean pods shatter due to non-availability of labourers for harvesting the crop in time, leading to reduced yield and loss. To solve this problem Bhagwan Singh decided to develop a reaper windrower machine.

This device has three different units namely, cutting unit, which consists of cutter bar, reel unit for pushing the standing crop towards the cutter bar and gathering unit to windrow the crop at centre of the machine thus making it easy to handle/transport to the threshing floor. It reduces manpower requirement and the drudgery involved in the harvesting process. The machine has 7 ft width of operation and can cover 0.4 hectares per hour. While operating this machine, fuel consumption of tractor is 2.5-3 litres per hour.N Sakthimainthan (Hand operated water lifting pump)

Tamil Nadu

He built five prototypes over a period of fifteen years before finally perfecting his design.

The resulting water-lifting device is operated by the continuously rotating a handle. It is simple in design and has a high discharge at low cost compared to the motorized pumps and conventional hand pumps.

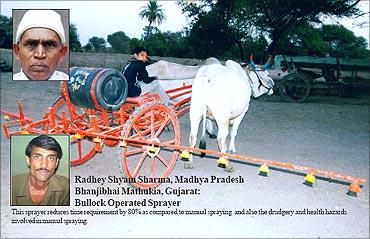

The pump has discharge of 20,000 lph at 0.75 m head. The unit has also been tested by TNAU, Coimbatore and improved by CMERI Durgapur. It is useful device for drainage as well.Radhey Shyam Sharma (Bullock operated sprayer)

Madhya Pradesh Bhanjibhai Mathukia

Gujarat

The bullock operated sprayer is pulled by a pair of bullocks and gets the drive from the ground through a gear box and belt pulley system.

When the operator shifts the lever to a higher gear, the frequency of strokes of the pump increases as a result of which more pressure develops in the container. The spray fluid, thus, atomizes into fine droplets with a wider swath. This sprayer considerably reduces time requirement as compared to manual spraying and also the drudgery and health hazards involved in manual spraying. It has 18 nozzles, spaced at a distance of 35 cm and can cover 3.5 acre/h.M. Nagarajan (Lemon cutter)

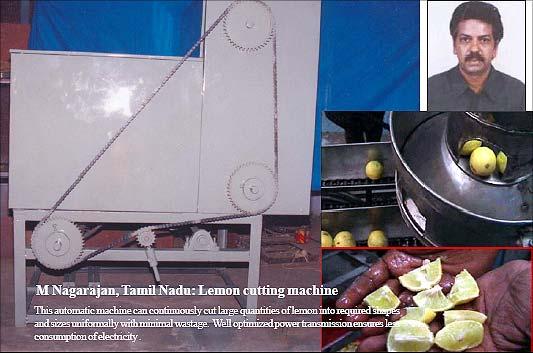

Tamil Nadu A small workshop owner from Uslampathy village in Tamilnadu, M Nagarajan has developed an innovative technology for cutting lime into small pieces in bulk quantity. This technology offers a great value proposition for the pickle manufacturing companies. The pickle industry suffers with a big problem of inefficiency in its operations due to low degree of automisation e.g. cutting of fruits is done manually. The second big problem, the industry faces is short-supply of labour during peak seasons, which limits the capacity. It is a novel machine in terms of its cost effectiveness, efficiency, drudgery reduction for women, safety considerations and transmission system.

P K Ravi (Pepper thresher)

Kerala

The Spices Board (Ministry of Commerce and Industry, Govt. of India) has recognised his innovation and included it in the Board's subsidy scheme.

About 100 kg pepper can be threshed in a one HP machine in ten minutes (60 kg in a HP version). It consumes 3/4 electric units per hour, has threshing efficiency 90 per cent and the damage is about 2-3 per cent.

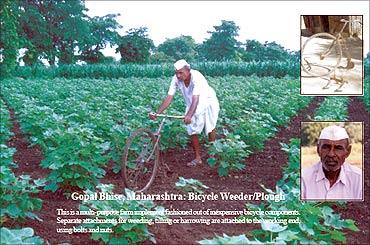

Gopal Bhise (Bicycle Weeder) Maharashtra

Bhise has fixed a rod with a blade at the end, to an assembly consisting of only the front wheel and the handle of a bicycle.He has named the assembly as 'Krishiraja', and claims it to be extremely efficient in removing weeds from hard land.

It is very useful device for ploughing/inter culture operation in very small farm plots, gardens and kitchen gardens. One can cover 0.08 hectare in one hour.Gurmeel Singh Dhonshi (compost Aerator & leaf pruner)

Rajasthan

Dhonshi's machine is a tractor PTO driven machine, which can thoroughly mix the bio-wastes and add moisture as well thereby reducing the time of decomposition.

The machine can cover a row of wastes disbursed by 100 trailers of size 11 ft x 6.5 ft x 2.5 ft (i.e total 400 ton) in one hour. Tractor consumes 3.5-4.0 liter diesel per hour. The compost has better fertility value as compared to FYM and vermin compost.Total time for converting the biomass into manure while processed by this machine is 25-40 days, which is otherwise 3-4 months by the conventional methods.

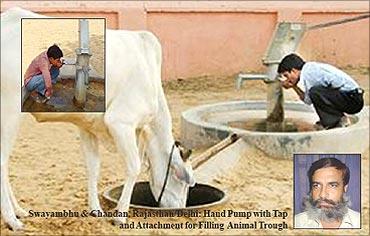

Swayambhoo Sharma, Madanlal Kumawat, Chandan Agarwal

(Modified hand pump with tap and attachment for filling animal trough) Rajasthan/Delhi

For human beings, the need gets addressed to some extent but for animals this need is much less appreciated.

Swayambhoo Sharma came up with an interesting solution to address the drinking water needs of animals.He developed an arrangement such that every time people pump water for their use, 20 per cent of pumped water will directly go to fill animal water trough. Since most people feel lazy in filling drinking water trough for stray animals, this innovations solves this problem by a kind of tax at source.

Another problem faced in hand pumps is that a single person finds it very difficult to pump and at the same drink water (without a vessel with him/her).

Chandan, then a first year student at IIMA came out with an idea of storing water in the body of the hand pump so that having pumped, one could use a tap and drink water like any other tap.

Yusuf Khan and Madan Lal Kumawat, two other innovators combined the idea of Chandan and Swayambhoo Sharma and developed a hybrid model.

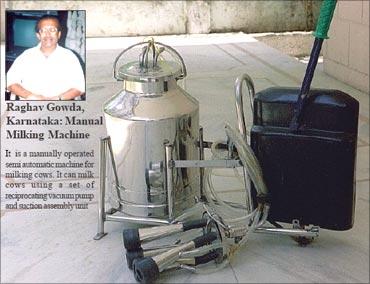

Raghav Gowda (Milking machine) Karnataka

Finding skilled labour for milking a small herd of cows is a problem faced by many farmers.But using machines for milking is a luxury which only a large farm or a dairy house can afford. Raghava decided to develop some method of milking, which would be affordable for all farmers.

The result: an easy to operate and low cost milking machine that can milk 1.5-2 litre of milk per minute.

The machine can be used to remove all the milk from the udder. The cow feels as if it is being suckled and does not experience any pain.

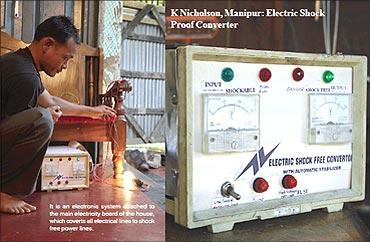

K Nicholson (Shock proof converter)

Manipur

The device can be installed just after the energy meter so that each and every connection in the building establishment gets connected to the device and becomes shock-free.

The innovator makes different variants based on application and user's requirements.CA Vincent (Floating soap)

Kerala

Vincent observed many people taking bath in rivers and ponds loosing their soaps, which often sink in the water.

He conducted experiments in his soap manufacturing unit for about 14 years to develop this unique process of manufacturing soap that floats in water. The soap has a density of 0.878, TFM (Total Fatty Matter) as 73 per cent, foaming stability as 0.1 cm and foaming power as 0.2 cm.Jina Khumujam (Herbal Soap)

Manipur

This is a soap made using milk, honey, oil, caustic soda, and soap-nut. Local herbs/plants having high medicinal value and health benefits are also been added.

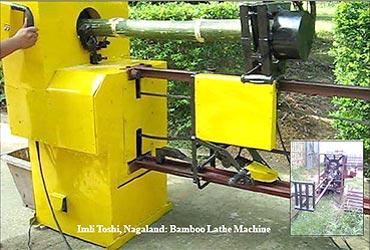

Imli Toshi (Bamboo lathe machine)

Nagaland

The machine developed by Toshi can do all the operations like removing the outer knots, smoothening the surface, internal/external carving and finishing.

The machine has soft touch joystick controlled operating system, which facilitates precision in operation.

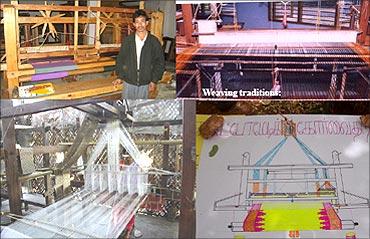

The finished bamboo can be used to make bamboo pet bottles. This bottle has the potential to replace the plastics and tin bottles and cans. The bamboo pet bottles can be made with a capacity of 1 lit, lit, 200 ml etc.Biren Singh (Improved Mechanized Loom)

Manipur

This innovative mechanized shuttle looms simulates the working principles of traditional Manipuri shuttle loom, except that the new machine runs fully automatic with the help of a half-horse power motor.

The output of the machine is 25-50 times more than the traditional shuttle loom, and almost any other power loom. The innovative machine can weave 3-4 fabric per hour whereas the traditional could hardly make 1-2 fabric in a day. Except for the change of bobbin, the machine doesn't require any manpower.

Manipur The innovative 'Double Shuttle Loom' works on the same principle as that of any other standard manual shuttle looms however, this new machine is broader in width and has provision for two sets of warp rolls. P L Bhanumurti (Automatic saree border weft insertion)

Tamil Nadu

Traditional Korvai or 'contrast' weaving involves intricate work where the design and the colour of the borders are often different from those of the main body of the sari.

Three shuttles are needed: the weaver operates two, and an assistant operates the third. Bhanumurti's automated system is derived from the "Catch Cord Technique drawing device for looms" so that no assistant is needed and the productivity is increased.

Mangi Singh (Kouna mat making machine)

Manipur

Kouna is synonymous with the exotic craft tradition of Manipur. This manual machine, which can even be operated by a low skilled worker or a physically challenged person, can weave two mats per day. The quality of the mats produced is better than those produced by traditional methods.

The productivity increases three to four times. A skilled traditional mat weaver can make only one mat in four days, including frill tying. The present machine can weave one mat per day, including frill tying.

Assam Conventionally, the task of the insertion of weft threads needed to make a variety of designs is done manually by tying knots, which is cumbersome and time consuming.

The thread is also wasted in connecting one motif to another. Deepak's innovative device makes designs in one third of the time required by the traditional way of making designs.

The device consists of three components; base frame, magnet bearing shaft and a specially designed bobbin. These components can be fitted to any handloom Jacquard machine. The attachment facilitates the Jacquard loom to perform automatic selection and lifting of warp threads for design making.

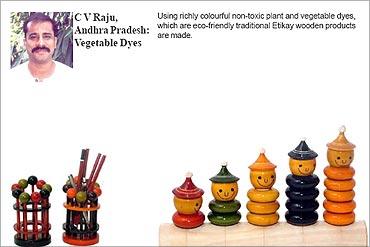

CV Raju (Vegetable dyes for wooden toys)

Andhra Pradesh

After 1910 the craftsmen had resorted to titanium oxide bonded synthetic colors for making wooden toys.

Raju's key strategy has been to strengthen the traditional local knowledge of making vegetative dyes, develop new tools, techniques and methods for increasing shelf life of the dyes and generate new uses.

Raju's experiments have resulted in many new toys imparted with vegetable dyes for which market is slowly emerging in India and abroad.

The toys of Etikoppaka imparted with vegetable dyes come in various shapes and forms ranging from toys to candle stands to vermilion boxes and bangles.Their enchanting designs, bright colors and earthly appeal are very attractive. Today, they are a part of the rural folk tradition.

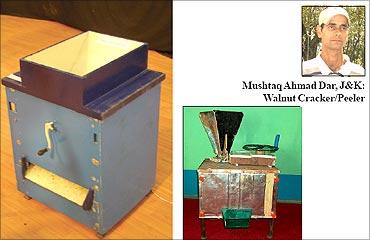

Mushtaq Ahmad Dar and Tauseef Ahmad (Walnut Cracker, Peeler & Washer)

Jammu & Kashmir

Manual cracking of walnuts involves a lot of time and drudgery. Mushtaq has come up with a walnut cracking machine which can process dry walnuts of various sizes, shapes and thickness to crack them open without damaging the fruit inside.

Peeling walnuts is a very labour intensive task involving a lot of drudgery. The sap of walnut skin burns hands and stains clothes as well.

The walnut peeler does away with all these problems. Using the walnut washer of Tawseef, the time required to wash, which otherwise is done manually using hands, has been reduced by over 60 per cent.The machine can process approx 80 kg of walnuts/h. The present version has cracking efficiency about 85 per cent, the peeler has capacity of 70 kg of green walnuts/ h. The washer has capacity of washing 90 kg walnuts/h.

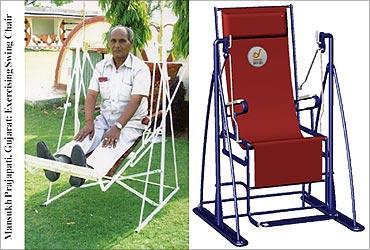

Sakrabhai Prajapati (Exercising chair- Maruti Jhoola)

Gujarat

Maruti Jhoola is a unique health chair with multiple capabilities, functions and settings for various postures and seating dynamics.

It is ergonomically designed and serves the purpose of seating as well as exercising for a person weighing up to 120 kg. It can double up as a hammock or a jhoola.

The health chair is useful for people suffering from arthritis and joint ailments.

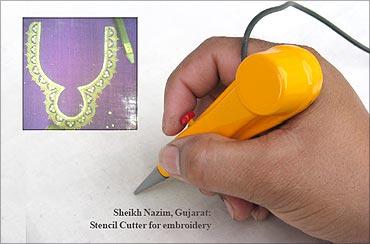

Sheikh Nazim (Stencil cutter)

Gujarat

Nazim has developed small innovative punching device to apply design on butter paper to facilitate designing on the cloth.

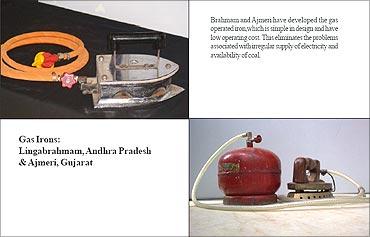

Brahmam, Ajmeri (gas-operated iron)

Brahmam and Ajmeri have developed the gas-operated iron,which is simple in design and have low operating cost.

This eliminates the problems associated with irregular supply of electricity and availability of coal.

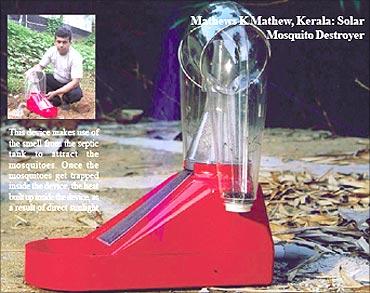

Mathews K Mathew (Solar Mosquito Destroyer)

Kerala

Heat builds up inside the device as a result of direct sunlight exposure. The trapped mosquitoes, thus, get killed due to the accumulated heat.

He has commercialised his product, on a small scale and will love to have partners who will scale it up. The innovator has also developed house fly trap.

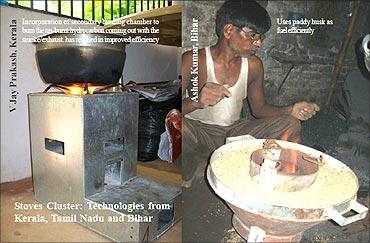

Ashok Thakur (Portable smokeless stove)

Bihar

It weighs 4 kg. It needs about one kg husk per hour.

V Jayprakash (Efficient wood stove)

Kerala

The stove has higher combustion efficiency in the range of 37.67% when wood is fueled and 29.48% when coconut shell is used as fuel.

C Senthil Kumar (Efficient wood stove)

Tamil Nadu

Different variants of the same for household and commercial use have been developed by Senthil Kumar. The innovator has sold over 15000 units of different versions of these stoves.

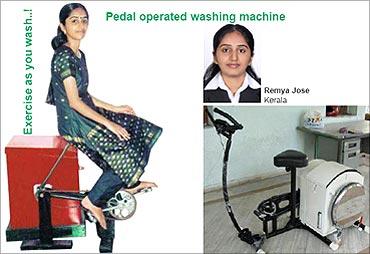

Remya Jose (Washing-cum-exercise machine)

Kerala

Remya Jose, then a class 11 student, thought of a simple, ingenious solution. She developed a washing machine which does more than just wash clothes. It even provides its users the chance to shed a few kilos!

Abhishek Bhagat (Automatic Food Making Machine)

Bihar

Who has not wished a machine, which would cook one's chosen recipe every time exactly as one wished it to be? But then such a machine will not elude us any more, if Abhishek's innovative food machine comes in the market.

This is a tested gadget with boxes in it to hold different ingredients and a display screen from which one can select options to cook different items.

Then, the screen displays the required quantity of each ingredient. Once the items are fed into the machine, it cooks the dishes.Source: rediff.com

Very nice post. N.K Dairy provides the high quality hand operated machine to the client at very reasonable rates. For more details you can read this blogpost now.

ReplyDeleteDid you know that you can shorten your urls with Shortest and receive money from every visitor to your shortened urls.

ReplyDelete